Welcome to Dove Die & Stamping

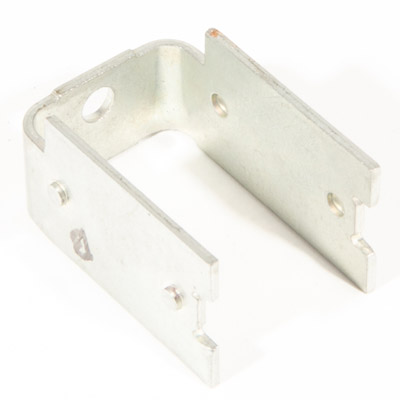

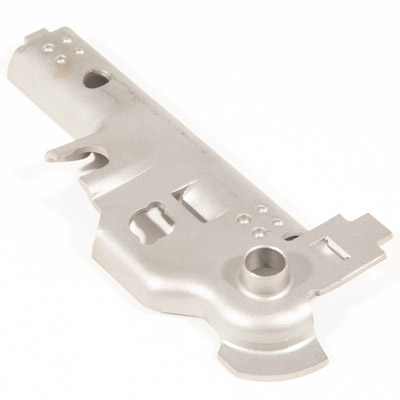

Dove Die & Stamping specializes in progressive die production stampings.

With almost 70 years of experience in the metal forming industry, Dove Die & Stamping has broad knowledge and expertise yet remains nimble enough to service ever-changing customer needs to ensure trust and satisfaction. From assemblies, sub-assemblies, large and individual parts to tooling designs and construction, Dove Die & Stamping is a reliable partner for precision metal components.

From engine timing systems and VCT components for the automotive industry, to decorative and functional parts for the plumbing industry, plus a variety of additional consumer products, Dove Die & Stamping gets the job done. The company has worked with hundreds of customer designs that have been manufactured into over a billion stamped parts.

100% Made In The USA

While many competitors in the industry have moved their production or parts of their supply chain overseas, Dove Die & Stamping has remained steadfast to a “Made in the USA” mantra, enabling a local supply chain for our customers that can react quickly. Prices are still competitive, quality is even higher, and customers have the ability to trust that deadlines will be met. All raw materials are sourced in the USA.